Screen-to-Machine Solutions

Integrate seamlessly with your machine.

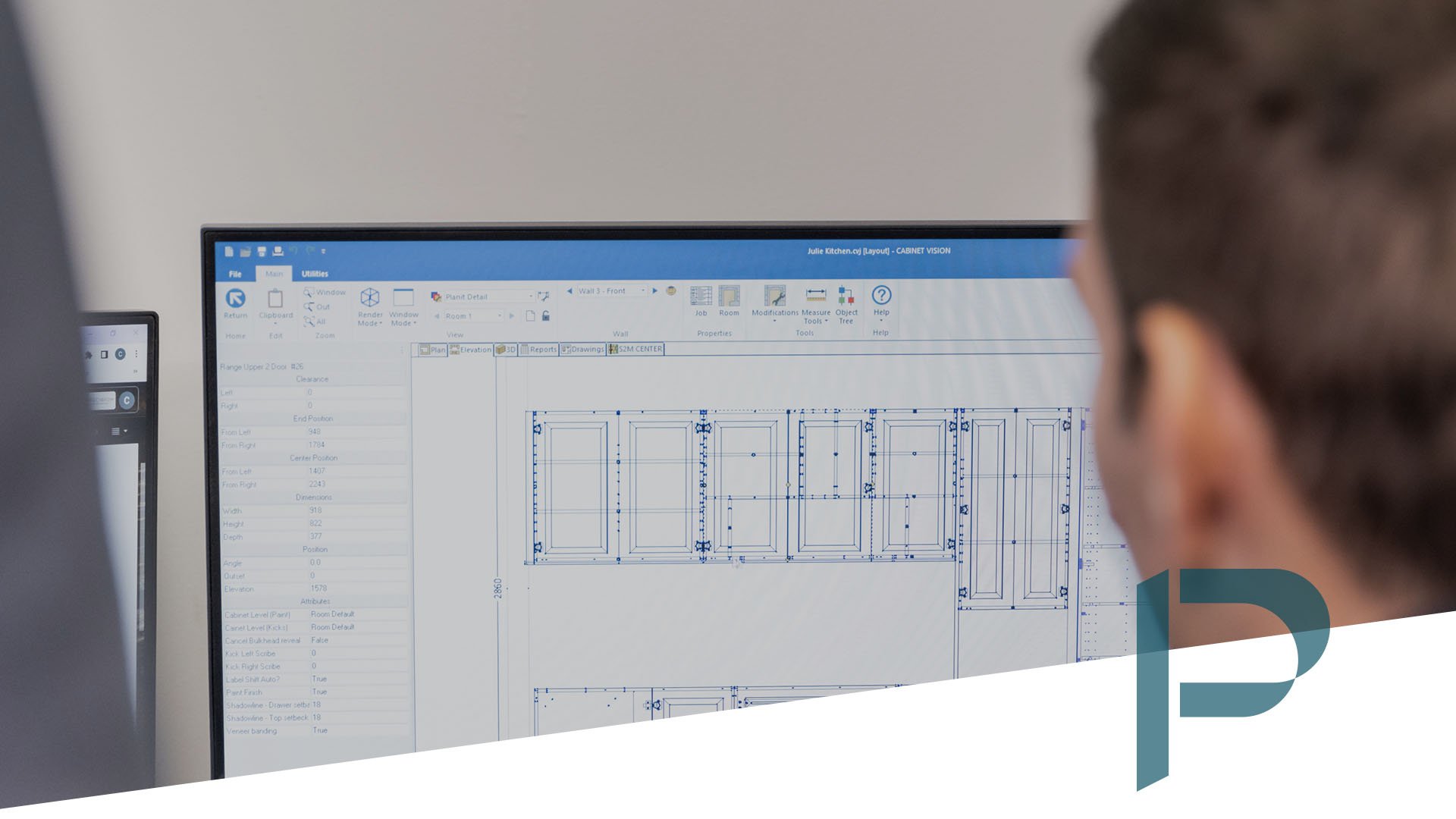

Planit’s range of Screen-to-Machine Solutions are perfect as they integrate seamlessly with your machine, and provides your business with the complete software solution.

Solutions made for the industry

Our Screen-to-Machine software seamlessly integrates with our CABINET VISION drawing solutions. This means you can complete your design, then send it to straight to your machine; all in the one program.

A Screen-to-Machine Solution gives you the flexibility to meet your clients’ needs and allows you greater control when producing the project. Maximise your machine investment by utilising your machines full capabilities. This intelligent machining saves enormous machine “programming” time when compared to older manual systems.

Machine Company Partners

-

SR

-

Morbidelli x200

Morbidelli x400

Pratika 310

-

P2

Enduro

M Series

-

Alberti Vector

Alberti T-Flight

Anderson GS

Anderson Gensis Plus

NCG2812

NCG3718

NCB612

-

One HS

Advance

Rapid

Hyper

-

Masterwood Winner

-

Rover A

Rover AS

Rover B

Rover K

Brema Eko

Brema Vektor

Selco SK

Selco WN

Winstore

-

Centateq

Drillteq

Vantage

Weeke

-

E3

E4

-

KN3

KN2

-

Tornado

Optimal capabilities

Our xMachining solution is capable of nesting, optimization, and is able to generate machine ready code for saws, point-to-point machines, CNC routers, Drill and Dowel Machines, Chop Saws, and other specialized woodworking machinery. Our range also has add-on options to further enhance your Screen-to-Machine solution, including our labeling solutions.

xMachining is designed to save you more money through reducing labour and material costs, by giving you greater control of your machine. Automate the entire design to manufacturing process by doing everything in the one program.

One of the key features of xMachining is the Linked Part Outlines. By creating a more efficient toolpath, the machine consequently works more efficiently. Using this feature can save you up to 15% on cycle times at your CNC.

With the ability to import DXF files, xMachining gives you greater flexibility with the work you can do. You are able to import files from other CAD applications.

Machine Brands

If your brand of Machine is not listed below, please contact the Planit Australia team.

-

Raptor Ultra

Extreme Ultra

Flexa Pro

-

Alberti Vector

Alberti T-Flight

-

Anderson GS

Anderson Gensis Plus

-

Horizontal Storage System

-

Winner

-

Morbidelli x200

Morbidelli x400

-

NCG2812

NCG3718

NCB612

-

KN3

KN2

-

Dynestic

Planit offers on-going support through our Help Desk.

We partner with businesses to ensure that the day to day is taken care of. Our support team are dedicated to ensuring you have help available when you need it.